Medium Voltage Cables, Installation Cables and Low Voltage Cables are produced as high-quality copper conductor energy cables for use in local electrical grids and building installations. In line with customer demands, these energy cables, which can be produced with various structures in accordance with specified standards, can be customized for different usage needs.

XLPE Cables: Strong Insulation and Safe Energy Transmission

Nominal Voltage: Low and Medium

Insulation Type: PVC (Polyvinyl Chloride), Cross-linked Polyethylene (XLPE)

Cable Structure: PVC filled, Steel armored

Additionally, cables designed specifically for customer requests can also be produced. Cable production is carried out with appropriate raw materials and precision machines according to specification requirements. Strict quality controls are applied at every stage of production and the safety and performance of the products are continuously monitored. When production is complete, the products are packaged in accordance with the specified specifications and made ready for shipment after passing the final tests.

XLPE (Cross-linked Polyethylene) Cables

XLPE cables are the preferred cable type for applications requiring high performance in energy transmission and distribution systems. XLPE, obtained by cross-linking polyethylene, increases the durability of the cable and its resistance to heat. Here are some features of XLPE cables:

Usage Areas

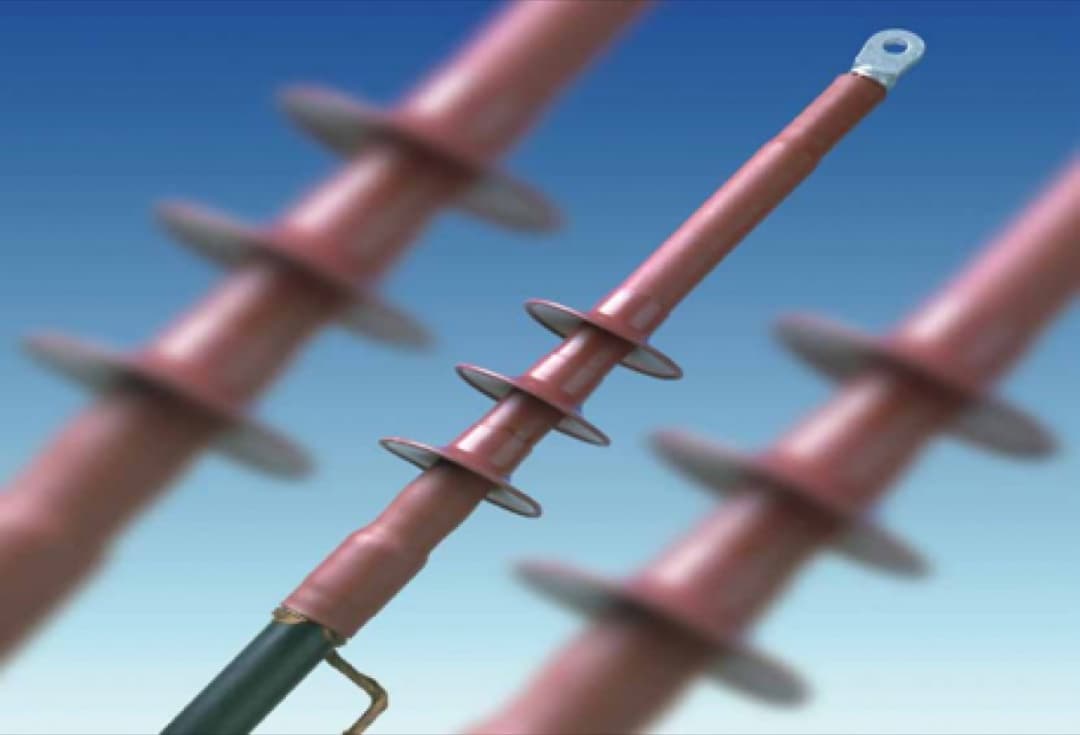

Cable Termination

Designed for medium voltage (between 1 kV and 36 kV) power cables, cable terminations provide safe and durable connections, increasing the efficiency and reliability of the energy infrastructure. These cable terminations ensure the long life of the system while minimizing maintenance needs. Thus, they ensure that energy transmission and distribution processes continue smoothly and safely. Medium voltage cable terminations are critical components that ensure the sustainability of the infrastructure and significantly increase the effectiveness of energy systems.

Features of Medium Voltage Cable Terminations

High Insulation and Protection

Medium voltage cable terminations are produced with materials that have high insulation properties. This feature prevents electrical leakages and provides a safe connection, thus increasing the stability of the system.

Easy Assembly

Cable terminations have designs that simplify the assembly process. Heat-shrink and modular systems shorten the assembly time and reduce labor costs. The need for special tools for assembly is minimized.

Suitability for Various Cable Types

A wide range of products is offered for different cable types (single-core, multi-core) and sizes, so users can find solutions suitable for their needs.

Long-lasting Durability

Cable terminations have designs that simplify the assembly process. Heat-shrink and modular systems shorten the assembly time and reduce labor costs. The need for special tools for assembly is minimized.

Advantages

Safety and Protection

These cable terminations provide protection against overcurrent and short-circuit situations, increasing the safety of the electrical system and ensuring its uninterrupted operation.

Usage Areas

They are widely used in switchyards, transformer stations, energy distribution networks and industrial facilities. They are also ideal for outdoor applications.